When Clean Air Isn’t So Clean

Air handling systems are built to create comfortable, controlled environments. Whether in homes, hospitals, office buildings, or greenhouses, HVAC systems move air across a network of filters, coils, drip pans, and ducts. Components are often exposed to moisture, organic particles, and temperature fluctuations.

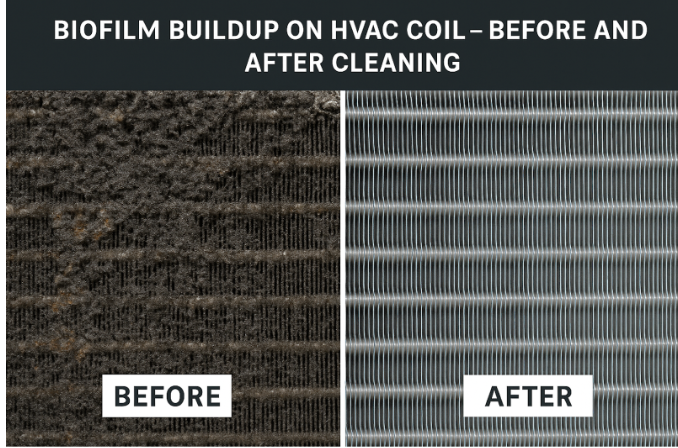

These conditions support the development of biofilm, a structured community of microorganisms that attaches to surfaces and forms a protective layer. Over time, biofilm becomes more resistant to standard cleaning and harder to detect. Once established, it can reduce airflow, limit heat exchange, and release bacteria, mold, or allergens into the circulating air.

The image below shows a typical example: an HVAC coil before and after biofilm removal. On the left, the coil is obscured by microbial buildup and corrosion. On the right, it is clean, fully exposed, and operating as intended.

Rew

The signs often appear gradually. A rise in energy costs, a decline in indoor air quality, or increased maintenance issues may all trace back to microbial buildup hidden inside the system. Because biofilm tends to form in areas that are difficult to access, standard cleaning routines often fail to eradicate it.

Preventing biofilm in HVAC systems is a standard part of hygiene practices. It helps maintain system efficiency and effectiveness. Biofilm influences air conditions within the system and contributes to wear on essential components. Let’s break down how biofilm forms, the risks it presents, and what can be done to control it effectively in various indoor environments.

What Is Biofilm and Why Does It Form in HVAC Systems?

Think of biofilm as nature’s way of creating microscopic cities. When bacteria and other tiny organisms find a comfortable spot to settle down, they don’t just live there alone; they work together to build what’s essentially a fortress around themselves. These microscopic communities stick firmly to surfaces and then construct their own protective bubble using a mix of sugars, proteins, and other natural materials they produce. This shield works remarkably well, keeping the inhabitants safe from cleaning products, preventing them from drying out, and protecting them from other environmental challenges that might otherwise harm them. The problematic part is that once these communities establish themselves, they’re incredibly stubborn to remove. Even after you think you’ve cleaned everything thoroughly, they often continue to grow underneath where you can’t see them.

Your heating and cooling system accidentally creates the perfect neighborhood for these microscopic settlers. The combination of moisture, comfortable temperatures, and steady air circulation is like rolling out the welcome mat. The trouble spots are predictable—those coils that get cold and collect water droplets, the pans that catch condensation, the drain lines that carry moisture away, and the inner surfaces of your ductwork. These areas naturally trap humidity and catch tiny particles floating through your home’s air. When those particles land and remain, they become a buffet for microorganisms seeking their next meal.

The process starts small and innocent enough. A few microscopic organisms drift in and decide they like what they find. They anchor themselves down with a thin, barely noticeable coating that helps them stay in place. But that’s just the beginning. From this foothold, the community begins to expand outward across the surface, usually remaining completely hidden from view. As more layers accumulate over time, the entire structure becomes increasingly complex to remove and develops stronger resistance to typical cleaning methods.

Systems running in naturally humid environments face the most significant challenges, especially when internal cleaning gets put off or forgotten entirely. The mathematics are unforgiving but straightforward; the longer these systems operate without proper attention to what’s happening inside, the deeper and more established these hidden communities become. This kind of microbial growth is not just a maintenance issue. Biofilm changes the way air moves through the system, affects temperature regulation, and can release harmful particles into occupied spaces. Understanding where and how it forms is crucial to implementing the most effective method of prevention.

Why You Shouldn’t Ignore Biofilm

It is easy to assume an HVAC system is working correctly as long as the temperature is consistent and the airflow seems normal. However, biofilm buildup inside coils, drain pans, and ductwork can gradually compromise system performance and air quality over time. One of the most immediate effects is a reduction in energy efficiency. Biofilm acts as a thermal barrier, making it harder for coils to exchange heat. Fans and compressors are forced to work harder than they need to. According to a peer-reviewed study published by the National Air Duct Cleaners Association (NADCA), cleaning HVAC systems can reduce fan and blower energy use by 41% to 60% and improve supply airflow by 10% to 46%. These improvements highlight how much energy can be lost when internal components are obstructed.

As biofilm matures, air quality can decline. The microbial layer can release bacteria, mold spores, and allergens into the air supply, potentially aggravating respiratory conditions or triggering allergic reactions. In sensitive environments such as hospitals, schools, and food handling facilities, this presents a significant risk. Moisture trapped within the biofilm can accelerate corrosion on metal components and contribute to foul odors or surface damage near vents and duct openings. These problems often go unnoticed until they begin to affect comfort or require costly repairs.

Because biofilm typically forms out of sight, it is not always part of a routine maintenance checklist. But ignoring it allows these issues to grow, often silently, until performance suffers and remediation becomes more complex.

Why Traditional Cleaning Isn’t Enough

Most HVAC cleaning focuses on visible debris and dirt buildup. Filters are changed, coils are rinsed, and surfaces are wiped down. These steps help reduce dust and debris but are insufficient to remove biofilm that has already formed. Biofilm creates a protective layer that shields microbes from the effects of surface disinfectants. Even if the top layer is cleaned, the deeper structure often remains in place, allowing the colony to regrow.

Many of the areas where biofilm forms are difficult to reach. Coils, drain pans, and duct interiors are often deep inside the system. Standard service tools are not designed to thoroughly clean or achieve these areas.

Some chemical products can break through buildup, but they may be corrosive or leave behind residues that are unsuitable for sensitive environments. If biofilm is already established, general cleaning will not solve the problem.

Smarter Solutions for Biofilm Prevention

Controlling biofilm requires more than surface cleaning. It involves consistent and thorough coverage of areas where microbial buildup is most prevalent, particularly within HVAC systems. One approach is to use automated misting systems that apply fine droplets throughout enclosed environments. The Genesis 360 misting system is engineered for precision application in indoor settings. Its fine droplet technology helps deliver coverage to surfaces that are often hard to access, such as evaporator coils, duct interiors, and condensate pans.

Disinfectants formulated for consistent and broad-spectrum performance can support microbial control in both HVAC systems and the surrounding environment. BotaniMax is one such option. It is formulated with plant-derived ingredients, including thyme, citrus, and wintergreen oils, and is EPA-registered. It uses multiple modes of action to break down pathogens and organic buildup, making it effective against bacteria, fungi, and viruses on both surfaces and in the air.

BotaniMax is biodegradable, pH-balanced, and designed for straightforward application when used as directed. It is suitable for HVAC cleaning in sensitive spaces, such as gyms, classrooms, and animal care facilities. It carries the EPA’s lowest toxicity classification, indicating minimal impact on surfaces and equipment when used as directed.

When used as part of a broader prevention strategy, each of these technologies can contribute to cleaner systems, better air quality, and longer equipment life.

What Comes Next: Building a Smarter Biofilm Prevention Plan

Biofilms often remain unnoticed until they begin to impact air quality, energy consumption, or system performance. Prevention is the most effective and most practical place to start. Begin by identifying risk areas such as moisture buildup, overlooked surfaces, and parts of the system that are difficult to clean. From there, consider technologies that support more consistent coverage. This might include misting systems or disinfectants that are appropriate for frequent application.

If you are evaluating your current HVAC maintenance plan or seeking safer, more efficient tools, we are here to help you explore what works best for your specific setting.