The Controlled Environment Paradox

Indoor farming has changed the landscape of agriculture. By moving crops into carefully managed spaces, growers can reduce risks from weather, pests, and seasonal changes. The goal is consistency in yield, quality, and food safety.

Unfortunately, the systems designed to protect crops can also create conditions that support unwanted growth. Bacteria and fungi thrive in the environments where fruits and vegetables do best. High humidity, limited airflow, and dense plant arrangements can create hidden pockets where pathogens take hold.

This isn’t just a theoretical worry. In the summer of 2021, the FDA (https://www.fda.gov/food/outbreaks-foodborne-illness/factors-potentially-contributing-contamination-packaged-leafy-greens-implicated-outbreak-salmonella), CDC (https://www.cdc.gov/), and state partners investigated a multistate Salmonella Typhimurium outbreak linked to packaged leafy greens produced in a controlled-environment, hydroponic indoor operation in Illinois. The outbreak resulted in 31 illnesses and four hospitalizations across Illinois, Michigan, Pennsylvania, and Wisconsin, confirming that even indoor, soilless farming systems must be vigilant about contamination risks.

When that happens, even a minor issue in one part of the system can impact the entire operation. Microbial threats are often invisible, but once they gain a foothold, they are difficult to contain. This brings us to ask an important question: How can growers maintain efficient and productive environments while keeping microbial risks in check?

Why Indoor Crops Are Vulnerable

Indoor farms are designed to optimize growth. Controlled lighting, temperature, and irrigation systems help plants thrive with less exposure to the stressors of traditional agriculture. However, those same conditions can also support the growth and spread of harmful microbes.

Humidity is one of the most significant contributors to this phenomenon. Moisture in the air encourages fungal growth, especially in areas where airflow is limited. Even brief periods of condensation on walls, pipes, or grow trays can provide enough moisture for spores to multiply.

Recirculating water systems, although efficient, can also present risks. If the water is not adequately filtered or treated, it can carry pathogens throughout the facility. Irrigation systems often introduce root-zone diseases like Pythium, and to a lesser extent Fusarium. Pythium, in particular, is well known for spreading rapidly through recirculated water, especially in densely planted and hydroponic setups. Fusarium is typically soil-borne, although it can also spread through contaminated tools or media under certain conditions.

To picture how this plays out, imagine rows of strawberries growing in a climate-controlled indoor system. The berries hang just above troughs of nutrient-rich water, and overhead misting lines maintain consistent humidity. If one section of the system starts to retain just a little too much moisture, especially around the base of the plants, the warm and damp conditions can quietly fuel fungal growth. Small patches of mold are known to travel through irrigation lines or spread through air movement to other zones.

Plant density also plays a role. Crops grown closely together limit air circulation and slow down drying between irrigation cycles. This creates small pockets of warm, damp air that are hard to see and harder to manage.

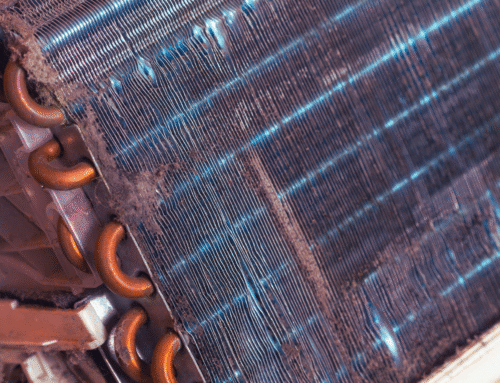

Even air handling systems, which are meant to stabilize the environment, can contribute to risk. Filters that are overdue for replacement or ducts with residual moisture can quietly reintroduce contaminants into otherwise clean areas.

The combination of these factors can form a chain of vulnerabilities that can be easily overlooked. Hidden conditions that favor the growth of bacteria and fungi can be present even in an operation that appears clean.

Current Prevention Challenges

Most indoor growers already follow sanitation protocols to reduce contamination risks. Routine cleaning, water treatment systems, and air filters are standard in many facilities. Still, harmful microbes often persist.

Coverage is a common challenge. Manual cleaning of trays, tools, and surfaces can miss areas that are difficult to reach or easily overlooked. As time goes on, bacteria or fungi can form biofilms. These thin, nearly invisible layers bond to surfaces and resist routine sanitation. These films can serve as reservoirs for future contamination.

Environmental monitoring is another weak spot. Conditions such as temperature and humidity are typically tracked at the room or system level, but what matters most is what happens in specific zones. A slight dip in airflow behind a vertical rack or a small buildup of moisture near a pipe fitting may not be visible in the data, but it can still create an environment for pathogens. Chemical disinfectants are widely used; however, they come with trade-offs. Some products can damage equipment or leave behind residues that raise concerns about food safety. Others lose effectiveness over time or require careful handling by staff. In some cases, overuse of certain chemicals may even contribute to microbial resistance.

Air handling systems provide another layer of protection, but they are often designed for general climate control rather than pathogen management. Without regular maintenance and proper filtration, these systems can circulate contaminants rather than remove them.

Even with solid protocols in place, it is challenging to mitigate every risk fully. Gaps appear in the details, particularly in areas that are hardest to see, clean, or control.

Innovations in Mitigation: A Smarter Path Forward

Many indoor growers are finding that traditional sanitation methods often fail to keep pace with the increasing complexity of modern operations. When managing a high-density system with tightly controlled airflow, water circulation, and plant proximity, even minor lapses in microbial control can have facility-wide effects.

To address these challenges, some operations are turning to automated misting systems that offer more consistent, facility-wide coverage. These systems utilize ultra-fine droplet technology to disperse disinfecting agents through the air, enabling a more comprehensive coverage across surfaces, equipment, and hard-to-reach areas.

One such system is Genesis 360 AGriGuardMist, a precision-engineered solution built specifically for indoor agriculture. AGriGuardMist provides clean and consistent misting without oversaturating grow lights, sensitive surfaces, or the plants themselves. The droplets are fine enough to reach into corners and enclosed areas, yet controlled enough to prevent buildup or excess moisture.

AGriGuardMist is designed for seamless integration into various growing environments, including greenhouses, vertical farms, aquaponic systems, and cultivation rooms. Automating both air and surface disinfection helps reduce disease pressure, supports equipment longevity, and enables growers to maintain compliance with sanitation standards. Misting adds an essential layer of proactive defense. It’s a method for managing microbial risk with precision, especially in environments where traditional cleaning methods can’t reach every surface or airflow pocket.

The Power of Natural Defense

Environmental control is a critical component of disease prevention, but many growers are also seeking suitable and effective methods to manage pathogens in high-risk areas of their facilities. Shared surfaces, storage zones, and worker spaces often become overlooked points of contamination.

This is where natural, plant-based ingredients can play a meaningful role. BAC Ag is one example. It is a product formulated with plant-based ingredients designed for use against a range of microorganisms. It has been evaluated for use against a broad spectrum of microorganisms.

When applied as part of a larger sanitation plan, botanical solutions like BAC Ag offer an added layer of defense without relying on corrosive chemicals or time-intensive processes. And because they are naturally derived, they align with sustainability goals and food safety standards.

A Layered Defense: What an Integrated Approach Looks Like

Preventing disease in a controlled growing environment isn’t about checking one box; it’s about maintaining a comprehensive approach. Most growers are aware that even with solid protocols in place, it only takes one overlooked detail for microbes to gain a foothold. That’s why many facilities are moving toward layered strategies that combine multiple methods of protection. This approach combines environmental controls with direct microbial management. For example, automated misting systems can help sanitize the air and surfaces throughout a facility. At the same time, natural botanical agents can be applied in high-risk zones where human contact, shared equipment, or moisture buildup increase the risk of spread.

Layered strategies also offer flexibility. Different crops and facility layouts call for different risk points. By combining suitable, targeted tools, growers can adjust their sanitation plan as needed without compromising efficiency or safety.

Here’s what a layered approach might include:

- Air and surface disinfection using automated misting systems

- Botanical applications for zones with frequent contact or high humidity

- Routine monitoring of moisture, temperature, and airflow across grow zones

- Regular equipment and touchpoint sanitation in worker and storage areas

- Preventive maintenance for HVAC, water lines, and filtration systems

The goal is to prevent problems before they reach the crop. And that becomes more realistic when prevention is built into every part of the system, not just added when something goes wrong.

Prevention Is Precision

Controlled environments offer clear advantages, but they also leave little room for error. When every part of a system is interconnected, significant problems can result from minor oversights. The growers who stay ahead of microbial risks are often those who treat prevention as part of their daily routine. Not a reaction to something going wrong, but a steady, thoughtful part of how the operation runs.

That doesn’t mean overcomplicating things. It means selecting tools and processes that work together to safeguard crops, equipment, and workers. A clean environment supports a productive one, and a layered strategy gives growers more control without relying on a single fix.

If you’re evaluating how to build a more resilient system, we’re here to collaborate with you. Let’s talk about what a layered approach could look like for your facility.