The controlled environment paradox

Indoor cultivation gives cannabis growers something outdoor farming cannot: consistency. You can dial in lighting, irrigation, temperature, and humidity, then repeat a recipe cycle after cycle. The challenge is that the same stable conditions that help plants thrive can also support unwanted microbial growth if sanitation is not built into the system.

This risk is not hypothetical. Food safety investigations have shown that controlled environment operations can still experience contamination events. In one multistate investigation tied to a controlled environment hydroponic indoor facility, public health agencies documented 31 illnesses and 4 hospitalizations linked to packaged leafy greens, as reported by the U.S. Food and Drug Administration (FDA) in its outbreak investigation summaries.

Cannabis is different from leafy greens, but the lesson holds. When microbes gain a foothold in an enclosed, high-humidity, high-density environment, they can spread quickly and quietly.

Why cannabis growhouses are vulnerable to microbial pressure

Cannabis cultivation creates several conditions that can elevate microbial risk:

- Dense canopies and limited airflow that trap moisture

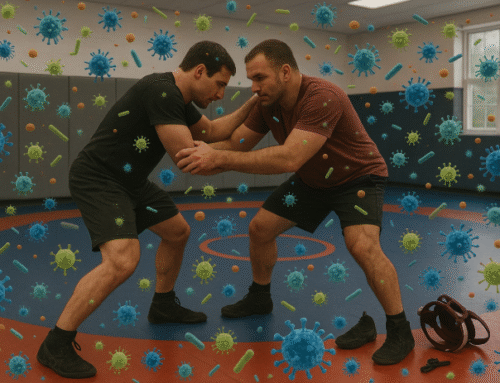

- Frequent worker movement that spreads organisms through touchpoints, tools, and clothing

- Room turns and harvest handling that move plant material and debris through the facility

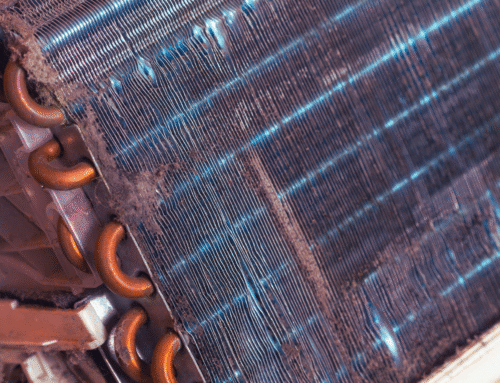

- Moisture and condensation on walls, lines, and equipment that give spores an easy place to persist

Peer-reviewed cannabis research consistently shows how handling and facility conditions influence microbial loads. A study published in Frontiers in Agronomy analyzed more than 2,000 fresh and dried cannabis samples collected between 2019 and 2022 and found that total yeast and mold counts were influenced by genotype, environment, and pre- and post-harvest handling practices.

Additional peer-reviewed research examining fungal contamination in cannabis reported the presence of Cladosporium, Penicillium, and Alternaria species on cannabis buds and noted that mechanical trimming increased the frequency of Penicillium species, likely due to tissue damage and microbial spread during processing.

This is why disinfection needs in cannabis farming are not just about cleaning better. They are about reducing baseline microbial pressure across the entire facility so the crop spends more time growing and less time responding to stress.

Where traditional cleaning falls short

Most cannabis facilities are already clean. They wipe surfaces, mop floors, sanitize tools, and follow room-turn protocols. The problem is coverage and consistency.

Manual cleaning often misses undersides of benches, rack structures, ducting, air handling areas, seams, textured surfaces, shared spaces, and low-visibility zones that rarely receive the same level of attention as production rooms.

Microbial control also becomes more difficult as operations scale. More rooms, more staff, and more movement increase the opportunities for organisms to transfer. If sanitation depends entirely on perfect manual execution every day, gaps will appear.

This is where environmental disinfection becomes a yield strategy. When the baseline environment is cleaner, it becomes easier to maintain compliance, reduce outbreaks, and keep rooms operating without disruption.

Automated environmental disinfection as a practical control layer

Secure Logic’s approach, as outlined in its guidance on microbial risk prevention in indoor growing facilities, focuses on adding a facility-wide layer of disinfection that improves coverage without oversaturating spaces. The article describes automated misting systems that disperse fine droplets through the air to reach surfaces and hard-to-access areas more consistently than manual application alone.

In a cannabis growhouse, this matters because contamination does not only live on obvious surfaces. Spores and microbes can persist on equipment housings, structural components, and in areas where plant debris accumulates. Scheduled, automated treatment helps reduce the chance that isolated contamination becomes systemic.

Automation also supports consistency. It helps prevent sanitation from depending on staffing variability, time pressure, or missed steps.

Using disinfectant application methods responsibly

Not every disinfectant is approved for every application method. According to the U.S. Environmental Protection Agency, unless a product label specifically includes directions for fogging, fumigation, wide-area application, or electrostatic spraying, those methods are not recommended, as safety and effectiveness have not been evaluated for off-label use.

The Centers for Disease Control (CDC) and Prevention similarly advises that foggers and sprayers should be used by trained personnel, following manufacturer instructions, appropriate contact times, and re-entry procedures, and only in suitable environments.

The value of automation comes from doing it correctly. That means using approved chemistries, following labeled application methods, and integrating disinfection into a repeatable, documented process.

What a strong automated environmental disinfection plan looks like

A plan that improves yield by reducing microbial pressure is usually built around layers rather than a single tactic.

First, room-turn sanitation removes organic matter before disinfectants are applied. Organic residue can shield microbes and reduce effectiveness.

Second, automated air and surface disinfection improves coverage in high-density rooms, vertical racks, and equipment-heavy areas. Secure Logic positions this as a way to support facility-wide consistency and proactive defense rather than reactive cleanup.

Third, high-risk zones such as trimming rooms, carts, door handles, and storage areas receive targeted attention. Secure Logic also discusses botanical, plant-based disinfection tools as part of a broader sanitation approach to reduce reliance on harsher chemistries where appropriate.

Finally, monitoring and discipline matter. Research shows that both environmental factors and handling practices influence microbial outcomes in cannabis. When processes change, sanitation plans must adapt accordingly.

Why this improves yield in real operational terms

Yield loss in cannabis does not always look dramatic. It often appears as reduced flower density, increased culling at harvest, more frequent contamination remediation, or failed microbial tests that lead to reprocessing or disposal.

Reducing background microbial pressure lowers the likelihood of these disruptions. Crops stay on schedule more often, room turns become more predictable, and labor shifts from emergency response to repeatable prevention.

That is how environmental disinfection becomes a yield driver.

Prevention is precision

Improving environmental disinfection does not mean overcomplicating operations. It means selecting tools and processes that work together to safeguard crops, equipment, and workers. A clean environment supports a productive one, and a layered strategy gives growers more control without relying on a single fix.

If you are evaluating how to build a more resilient system, we are here to collaborate with you. Let’s talk about what a layered approach could look like for your facility. Reach out to us today to schedule a call: